Consultation

Consultation

13640787503

All materials and parameters on the website are for reference only. The specific materials and parameters are subject to the actual products.

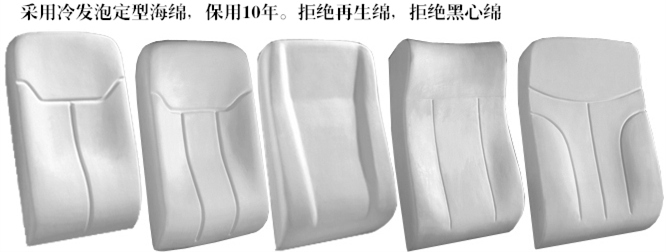

1. Back sponge: high density cold foaming Pu shaped sponge. The length of the back sponge is 700mm, the width is 450mm, the thickness is 90mm, and the density of the sponge is 45kg / m3.

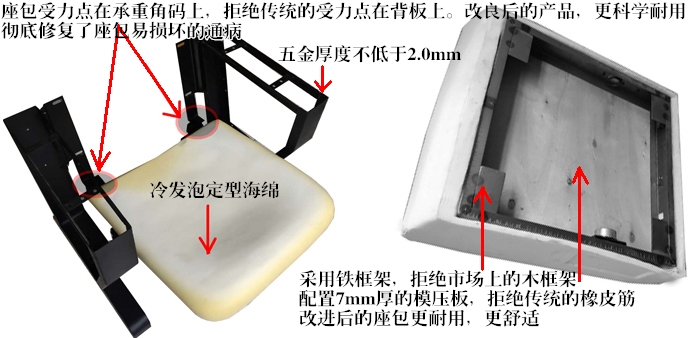

2. Block sponge: high density cold foaming Pu set sponge. The length, width, thickness and density of the sponge are 460mm, 425mm, 100mm and 60kg / m3 respectively.

3. Back inner board: it is made of high-quality and high-density hardwood multi-layer plywood, which is cold pressed and refined by the mold. It is beautiful, colorfast and deformation resistant. Size specification: 690mm in length, 425mm in width and 10 mm in thickness.

4. Base plate: it is made of high-quality and high-density hardwood multi-layer plywood by cold pressing and refining. It is beautiful, colorfast and deformation resistant. Size specification: 440mm in length, 400mm in width and 10 mm in thickness.

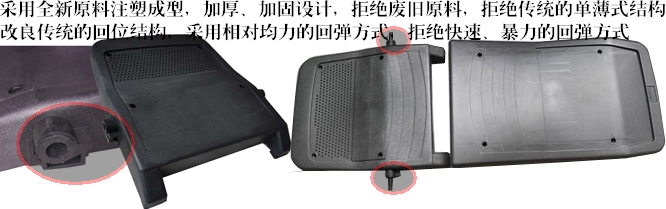

5. Seat back shell: made of high-quality PP (polypropylene) multi-element composite mold by injection molding. The base shell is designed with a noise elimination hole.

Back glue shell: length: 740mm, width: 450mm, thickness: 3.0mm

Base rubber shell: length: 500mm, width: 430mm, thickness: 4.0mm

6. Handrail frame and stand foot: it is made of 2.0mm thick high-quality steel plate, steel pipe by stamping and welding. The surface is treated by advanced oil removal, rust removal and phosphating. It is treated by epoxy polyester powder electrostatic spraying without coating, high-temperature plasticizing, with flat appearance, rust free and corrosion-resistant. The coating of fusion bonded epoxy powder does not meet the national standard GB / t18593-2001. Movable foot design, no need to be fixed on the ground

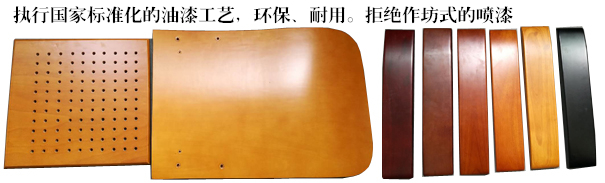

7. Tablet Kit: the tablet mechanism adopts fold over design and is equipped with silencing washer. The supporting and connecting structures are made of high-quality steel by oil pressure. The board surface is high-density board, covered with melamine surface, and the color is optional.

8. Seat return structure: high quality Φ 14 steel pipe is used, through-hole at both ends is fixed with 8 * 25 round head inner hexagon, and return is fixed with 3.5 torsion spring stainless steel screw, with accurate return and no noise.

9. Handrail cover: it is made of high-grade log, the solid wood is dehydrated, dried and buffered, and the exterior is covered with environmental protection paint, in accordance with GB18581-2001,

10. Fabric: advanced special fabric, anti pollution, anti-static, anti fading, fabric color, variety according to user choice,

11. Side plate: high quality and high-density board is adopted, which is formed by die stamping. The surface is pasted with 3mm thick high-density sponge, with high-grade fabric facing. The side plate is installed with glue nails and buckled on the handrail frame, which is stable and beautiful.

12. Basic dimensions and structure of seat: center distance: 580mm, seat cushion height from the ground 430-450mm, back height from the ground 1020mm. The minimum row spacing is 900mm, and the minimum installation radian is 15m. After the seat bag is opened, the rear stress is on the back corner code,

13、 Seat appearance: the design conforms to the principle of ergonomics and has good comfort.

14. Ground fixation: special top explosion screw is used to fix the seat and ground. Top explosion screw is divided into two parts: ground explosion rubber sleeve and screw

1、

2、

3、

4、